project overview

In this project, I build a chair from scratch using natural and recycled materials in a process that is as free from petroleum as possible. This was an eight-month project performed for my 2023 MFA Thesis Exhibition at the University of Notre Dame.

This project proposes a low-impact model of production and uses renewable, locally sourced bio-composites. Many of our furnishings and modern building materials are designed to be made in high volume and as cheaply as possible. This has led to an endless flow of petroleum-derived plastics, epoxy-soaked timber, and toxic adhesives that are impossible to reuse or recycle. The popularity of home renovations and imported fast-furniture in our consumerist culture ensures this direct-to-landfill trend will endure. This project seeks to disrupt this cycle by re-localizing manufacturing and bringing a renewed interest in place, purpose, and materiality to a new line of products.

Bioplastics blended with agricultural waste fibers (native grasses, wheat straw, natural dyes) yield materials with unique aesthetics while augmenting properties and improving their sustainability. In this project, I design and fabricate a chair that has an ultra-low carbon footprint and is free from petroleum and dangerous airborne chemicals, formaldehyde, chlorine, and phthalates. Modern digital fabrication technologies are leveraged to create customizable mold inserts and precision sheets, profiles, and patterns. Through the versatility, strength, and beauty of these materials, the chair will demonstrate the rich possibilities of low-carbon production.

Chair Prototyping and Fabrication Video:

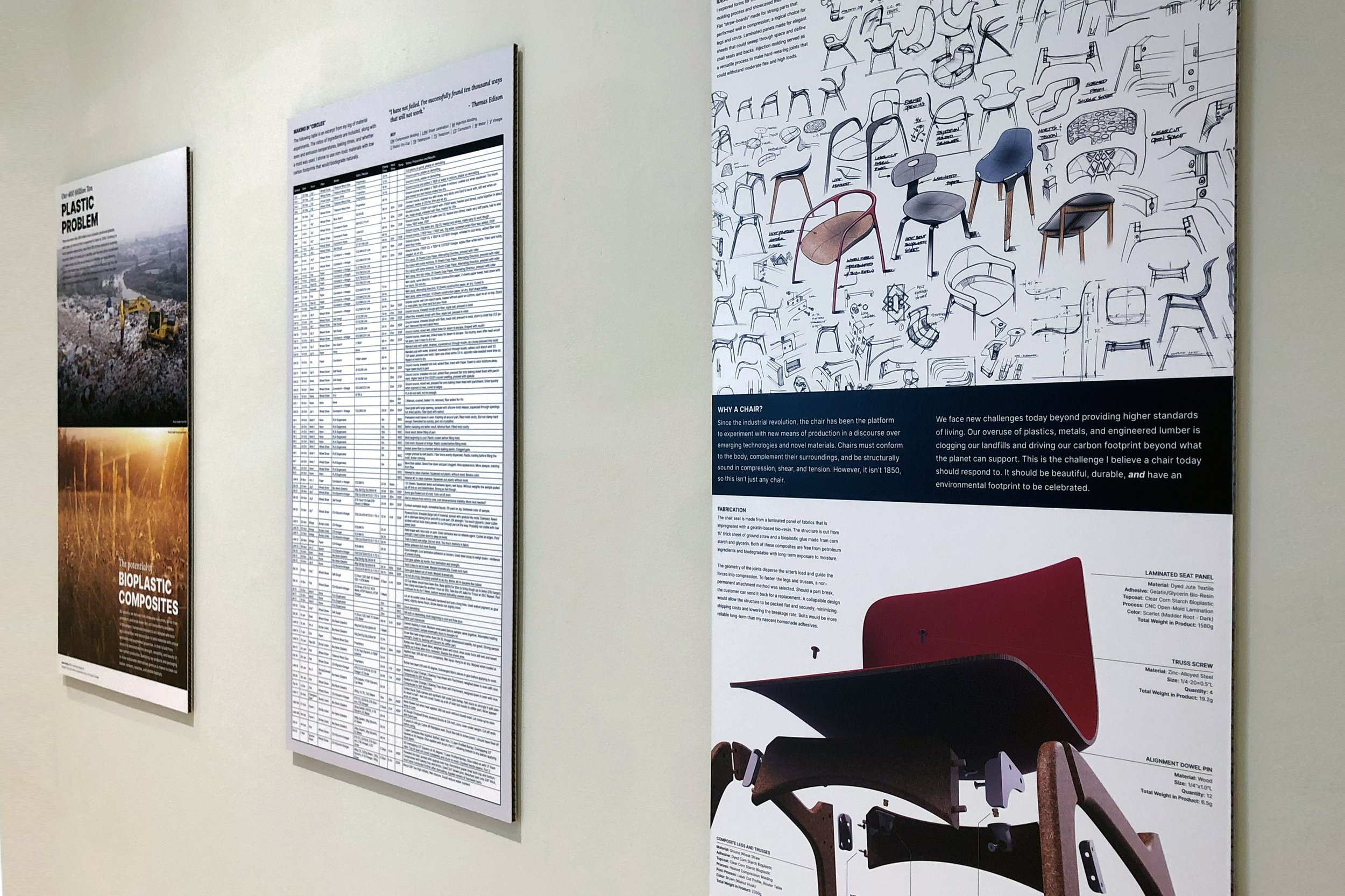

Exhibition Photos:

Research and Design Process

For my thesis project, I wanted to wade out of the conceptual space and reckon with our modern means of production. The goal of this project was not to build a chair. This was about embarking on a self-directed journey to understand the challenges of prototyping with sustainable alternatives to conventional manufacturing methods.

Background

It cannot be understated how much we rely on fossil fuels - from plastic formulations to adhesives, paints and lacquers, packaging, and the vast amount of fuel that supports global trade. Plastics may be used only for a short time but take hundreds of years to break down, infiltrating our planetary systems. Our use of these materials is responsible for 8% of global greenhouse gas emissions and is projected to triple in just over seventeen years.

This extractive relationship with resources is not exclusive to plastics. Timber, whose demand is already skyrocketing, will be driven even higher as it is seen as the low-carbon alternative in the race to curb emissions by 2050, the international initiative called Net Zero. This timber needs to come from somewhere, and currently just 13% of global forests are sustainably managed. Old growth forests are being converted to monocultures like eucalyptus, bamboo, rubberwood, and spruce, privatizing these once biodiverse regions, and pushing out workers who made a living from the land for generations.

Guided by numerous case studies and the sustainability scholars David Orr, William McDonough and Daniel Wahl, I’ve questioned whether production can be productive? More specifically, can the fabrication of a product support the collection of waste materials, share economic opportunity, and fund the growth of plants that improve ecological resilience.

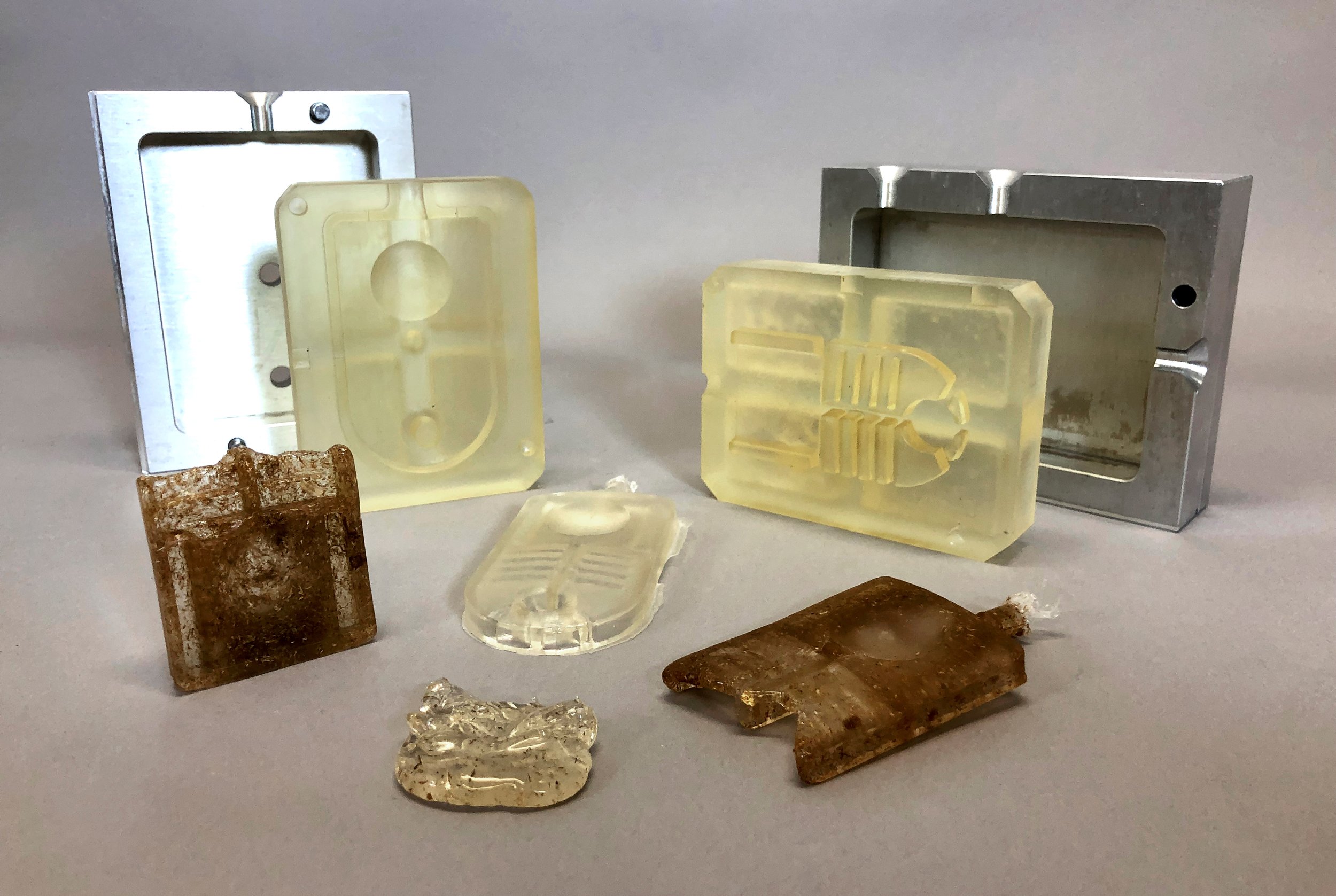

In the fall semester, I created and tested over a hundred samples of bioplastic composite materials. Bioplastics are derived from renewable resources, rather than petroleum, and break down into soil components and water. When blended with a fiber or an aggregate, it becomes a composite, possessing augmented properties, aesthetics, and cost.

Wanting to see this process through from start to finish, I grew my own plot of prairie grasses and cereal crops over the summer. I harvested in October, leaving ground cover to shelter the soil from the winter sun, reduce erosion, and provide overwintering habitat for wildlife. I bundled the fiber in stooks, an ancient technique for drying grain in the sun, instead of kilns.

Three of these materials show promise, and with further testing, may be commercialized. Compression-molded ground straw blended with a bioplastic paste targets conventional OSB, MDF, and plywood; formed fabric panels laminated with bio-resin targets conventional fiberglass and elastomers; and sugarcane PLA blended with wheat, hemp, or flax powder targets conventional injection-molded plastic. These composites are free from petroleum ingredients and biodegrade with long-term exposure to moisture.

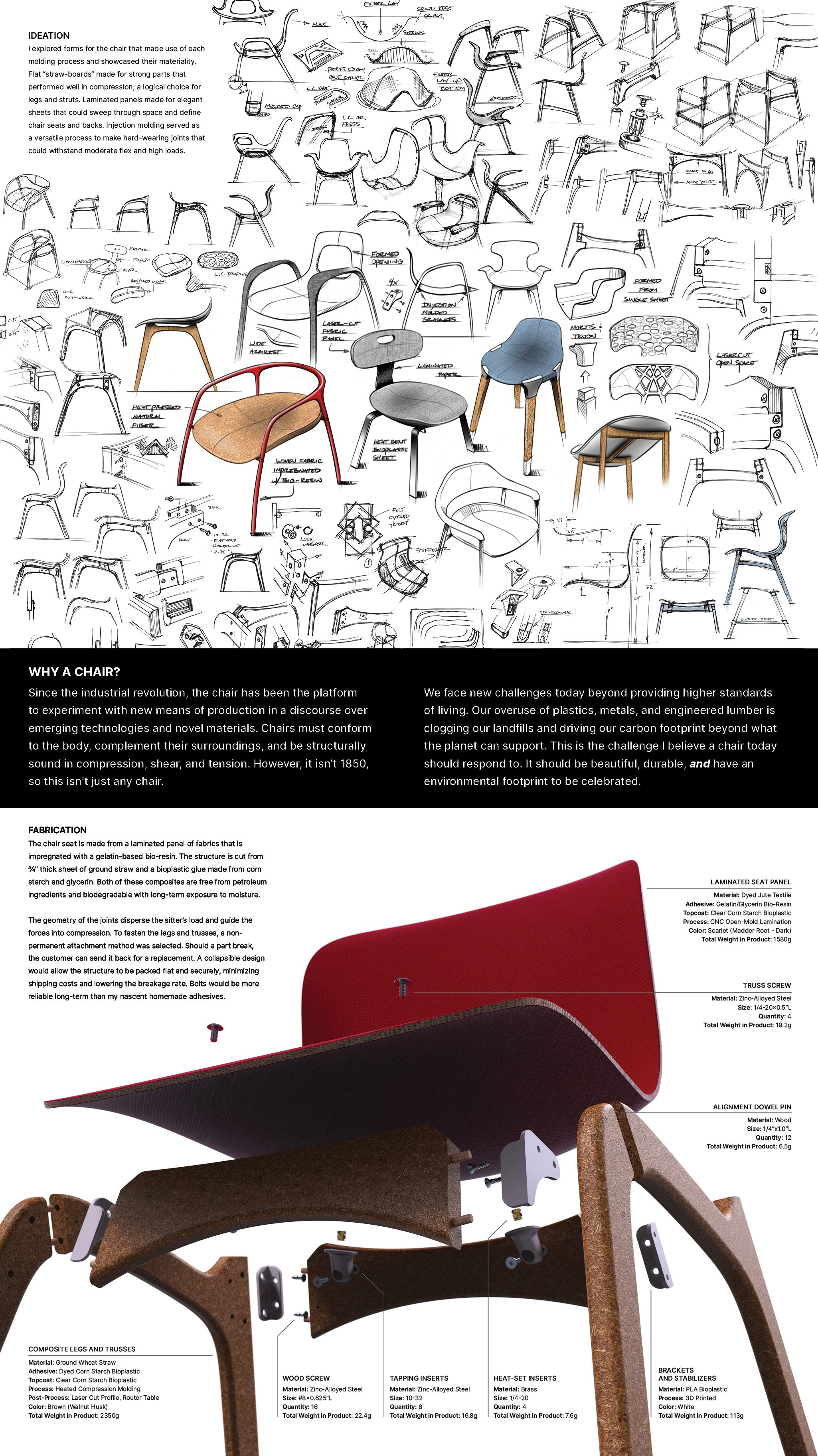

Design Process

My concepts for the chair made use of each molding process and showcased their materiality. With digital fabrication, I could achieve contemporary, high precision forms. The final design is fashioned as a task chair for public spaces, like schools or conference halls. It has a contoured seat with lumbar support for upright posture and a gentle lean.

The chair seat is a laminated panel of fabrics that are impregnated with a gelatin-based bio-resin. The structure is cut from ¾” thick sheet of ground straw and a bioplastic glue made from corn starch and glycerin. Homemade bioplastics are blended with local agricultural fiber and natural dyes to yield the chair’s seat, legs, trusses, and brackets, representing 98.2% of the chair’s mass. The rest is composed of metal hardware, allowing the chair to be repaired and packed flat.

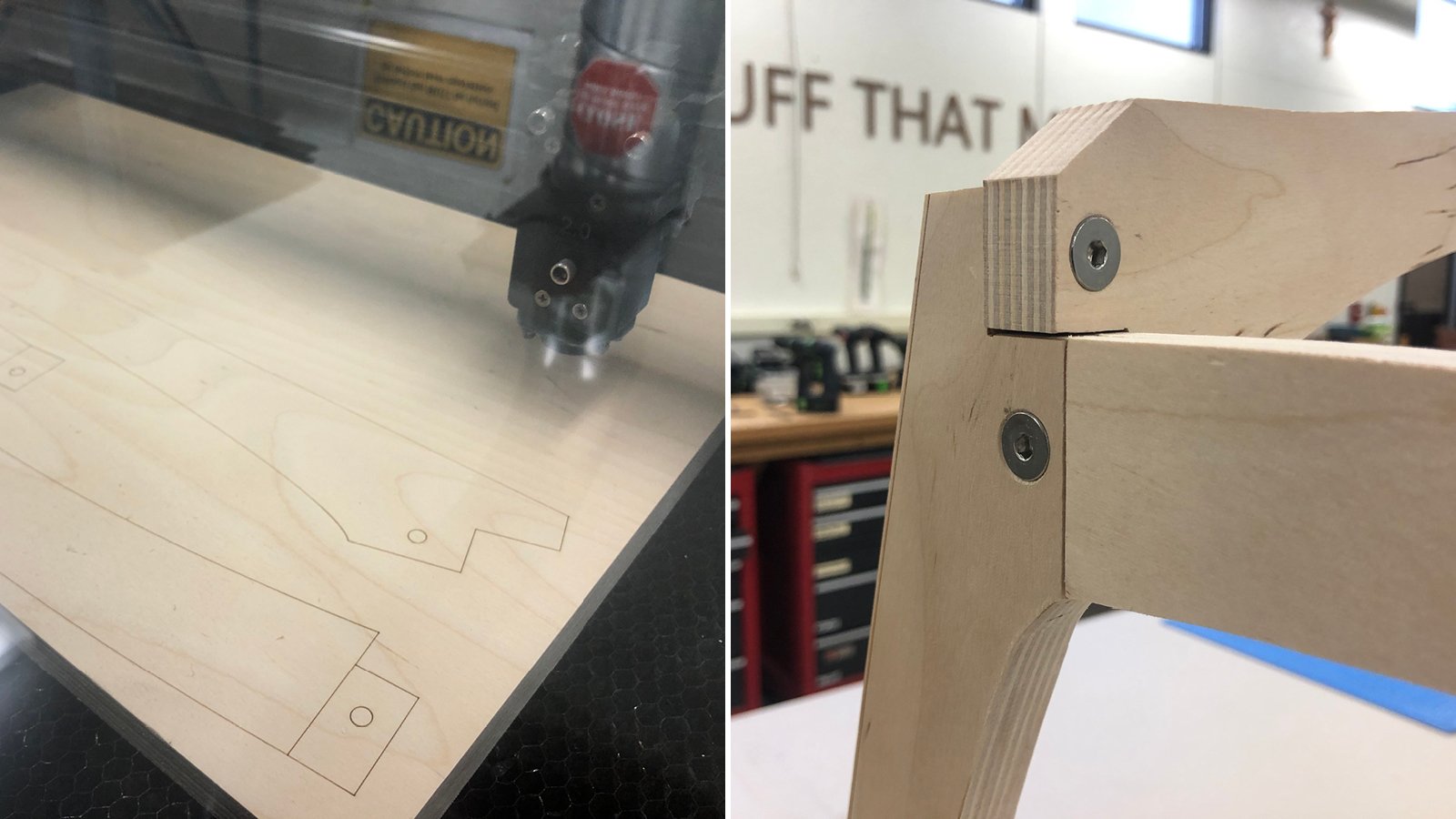

Lasercut Leg Pattern: The Chair’s legs and trusses were designed to be cut from a single 24” x 16” Straw-Board. One 4’ x 8’ sheet could yield the base for twelve chairs. All of the scrap is reground for later use.

Life Cycle Assessment / Implications

For an objective evaluation of how “sustainable” this chair is, I’ve used the IDSA’s Okala Method to perform a life cycle assessment of this chair against two common competitors. This chair’s footprint is roughly half of an aluminum and plastic chair, and a third of one that is plated steel and fiberglass.

In working on this project over the last eight months, I feel like I’ve just scratched the surface and am excited to see where this practice goes next. While it isn’t easy, fabricating with regionally produced, natural materials can dramatically lower the environmental footprint of our goods and supply chains, and demonstrate that materials not derived from petroleum can be viable and attractive alternatives.